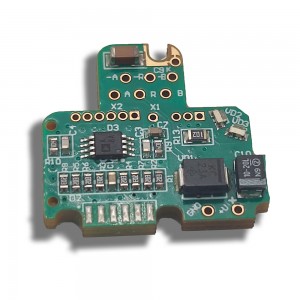

6 Layers Vehicle GPS PCBA Module

Basic Info

| Model No. | PCBA-A29 |

| Assembly method | SMT+Post Welding |

| Transport package | Anti-static Packaging |

| Certification | UL, ISO9001&14001, SGS, RoHS, Ts16949 |

| Definitions | IPC Class2 |

| Minimum Space/Line | 0.075mm/3mil |

| Application | Vehicle Tracking |

| Origin | Made in China |

| Production Capacity | 720,000 M2/Year |

Product Description

As a PCB OEM manufacturer from Shenzhen, China, ABIS Circuits provides a wide range of Printed Circuit Board Assemblies (PCBAs) for various applications, including vehicle tracking. The PCBA-A29 is a 6-layer module designed for GPS tracking in vehicles, with dimensions of 105.08mm*57.06mm and a board thickness of 1.6mm. The base material used in the module is FR4, which is a flame-retardant material that is widely used in the electronics industry.

The PCBA-A29 is assembled using two different methods, namely Surface Mount Technology (SMT) and Post Welding. Both these methods are used to mount electronic components on the PCB, but there are some differences between them.

SMT is a process where electronic components are mounted directly onto the surface of the PCB. This is done by placing the components onto the PCB's solder pads, which are pre-coated with a layer of solder paste. The PCB is then heated, which causes the solder paste to melt and bond the components to the board.

Post Welding, on the other hand, is a process where components are first inserted into holes in the PCB, and then the leads are soldered onto the board's pads. This process is also known as Through Hole Technology (THT). Post welding is commonly used for components that are too large to be mounted using SMT or for components that require a high degree of mechanical strength.

The PCBA-A29 module is assembled using both SMT and Post Welding. SMT is used for mounting smaller components, while Post Welding is used for larger components that require mechanical strength. This combination of methods ensures that all components are securely mounted on the PCB, providing a reliable and stable module for vehicle tracking.

In addition to the assembly method, the PCBA-A29 module is packaged using anti-static packaging to protect it from electrostatic discharge during transportation. This ensures that the module is delivered to the customer in optimal condition, ready to be integrated into their vehicle tracking system.

Overall, the PCBA-A29 module is an excellent example of the high-quality PCBAs produced by ABIS Circuits. With its 6-layer design, SMT and Post Welding assembly, and anti-static packaging, it provides a reliable and stable solution for vehicle tracking applications. As a PCB OEM manufacturer, ABIS Circuits is dedicated to providing the highest quality products and services to its customers, and the PCBA-A29 module is no exception.

Q/T Lead Time

| Category | Quickest Lead Time | Normal Lead Time |

| Double-sided | 24hrs | 120hrs |

| 4 Layers | 48hrs | 172hrs |

| 6 Layers | 72hrs | 192hrs |

| 8 Layers | 96hrs | 212hrs |

| 10 Layers | 120hrs | 268hrs |

| 12 Layers | 120hrs | 280hrs |

| 14 Layers | 144hrs | 292hrs |

| 16-20 Layers | Depends on the specific requirements | |

| Above 20 Layers | Depends on the specific requirements | |

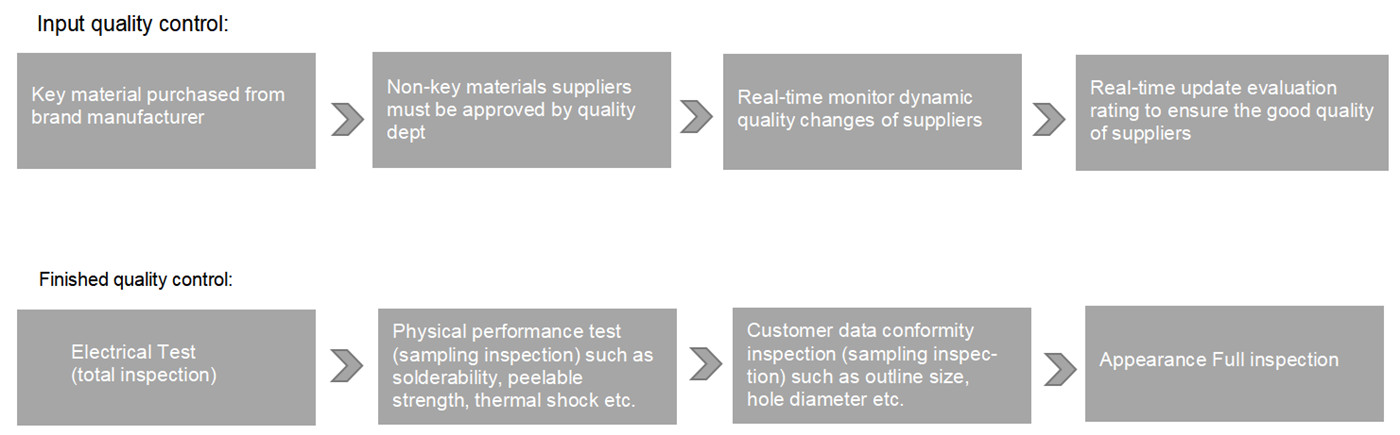

Quality Control

Certificate

FAQ

A: We usually quote 1 hour after we get your inquiry. If you are very urgent, please call us or tell us in your email.

A: Free samples depend on your order quantity.

A: It's no problem. If you're a small wholesaler, we would like to grow up with you together.

A: Generally 2-3 days for sample making. The lead time of mass production will depend on the order quantity and the season you place the order.

A: Please send the details inquiry to us, such as the Item Number, Quantity for each item, Quality request, Logo, Payment Terms, Transport method, Discharge place, etc. We will make an accurate quotation for you as soon as possible.

A: Each Customer will have a sale to contact with you. Our working hours: AM 9:00-PM 19:00(Beijing Time) from Monday to Friday. We will reply to your email as soon as quickly during our working time. And you also could contact our sales by cellphone if urgent.

A: Yes, we are pleased to supply module samples to test and check the quality, mixed sample order is available. Please note buyer should pay for the shipping cost.

A: yes, We have a professional drawing engineers' team that you can trust.

A: Yes, we ensure that each piece of PCB, and PCBA will be tested before shipment, and we ensure the goods we sent with good quality.

A: We suggest you use DHL, UPS, FedEx, and TNT forwarder.

A: By T/T, Paypal, Western Union, etc.