Customized Copper Substrate PCB High-frequency Circuit Board for Telecom Industry with Thick Copper

Product Description

PCB board Circuit Board with UL, SGS, ISO Certificates

- Single, Double side & Multi-layer PCB

- Buried/Blind Vias, Via in Pad, Counter Sink Hole, Screw Hole(Counterbore), Press-fit, Half Hole

- HASL lead-free, Immersion Gold/ Silver/Tin, OSP, Gold plating/finger, Peelable mask

- Printed Circuit Boards adhere to IPC Class 2 & 3 international PCB standard

- Quantities range from prototype to medium&big batch production

- 100% E-Test

Technical & Capability

| ITEM | CAPABILITY | ITEM | CAPABILITY |

| Layers | 1-20L | Thicker Copper | 1-6OZ |

| Products Type | HF(High-frequency) &(Radio Frequency)board, Imedance controlled board, HDIboard, BGA & Fine Pitch board | Solder Mask | Nanya & Taiyo; LRI & Matt Red. green,yellow, white, blue, black |

| Base material | FR4(Shengyi China,ITEQ, KB A+,HZ),HITG,FrO6,Rogers,Taconic,Argon,Nalco lsola and so on | Finished Surface | Conventional HASL,Lead-free HASL,FlashGold,ENIG (lmmersion Gold) OSP (Entek),lmmersion TiN, lmmersion Silver,Hard Gold |

| Selective Surface treatment | ENIG(immersion Gold) + OSP ,ENIG(immersion Gold) + Gold Finger, Flash Gold Finger, immersionSlive + Gold Finger, Immersion Tin + Gold Finger | ||

| Technical Specification | Minimum line width/gap: 3.5/4mil (laser dril) Minimum hole size: 0.15 mm(mechanical drill/4 mill laser drill) Minimum Annular Ring: 4mil Max Copper thickness: 6Oz Max Production size: 600x1200mm Board Thickness: D/S: 0.2-70mm,Mulltilayers: 0.40-7.Omm Min Solder Mask Bridge: ≥0.08mm Aspect ratio: 15:1 Plugging vias capability: 0.2-0.8mm |

||

| Tolerance | Plated holes Tolerance : ±0.08mm(min±0.05) Non-plated hole tolerance: ±O.05min(min+O/-005mm or +0.05/Omm) Outline Tolerance: ±0.15min(min±0.10mm) Functional test: lnsulating resistance: 50 ohms (normality) Peel off strength: 14N/mm Thermal Stress test: 265C.20 seconds Solder mask hardness: 6H E-test voltage: 50ov±15/-0V 3os Warp and Twist: 0.7%( semiconductor test board 0.3%) |

||

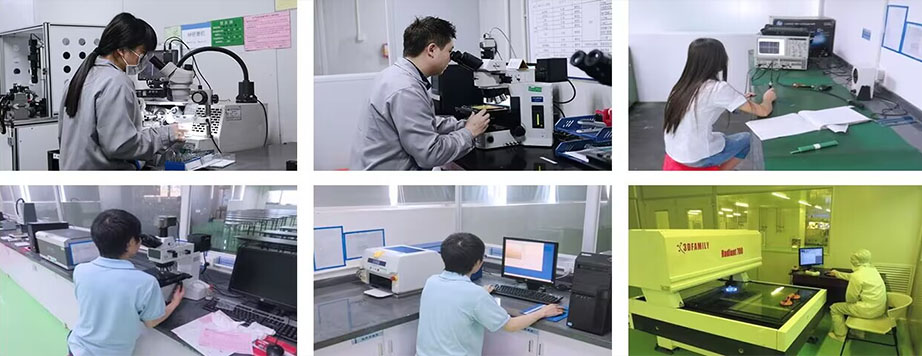

Company Profile

ABIS Circuits Co., Ltd established in 2006, Located in Shenzhen, our company has about 1100 workers and two PCB workshops with about 50000 square meters.

Our products are mostly used in the field of industrial Control,Telecommunication, Automotive products,Medical, Consumer, Security and others.

Our perfect management, advanced equipment, and professional staffs are the keys for us to fight to win more market shares with other competitors.Customer satisfaction and support are what we have been strived for.

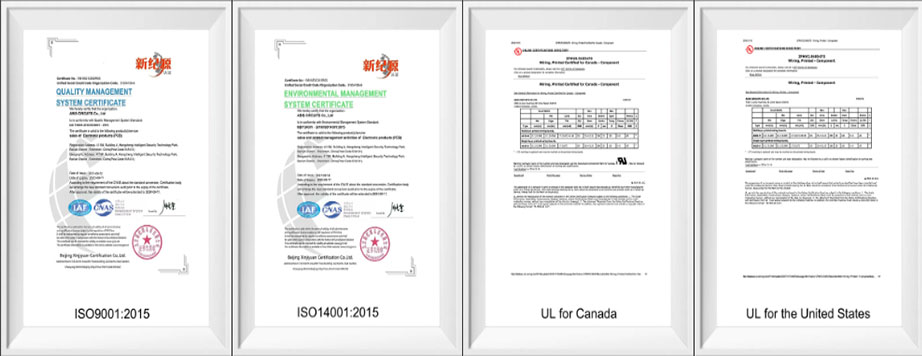

Now we have passed lSO9001, ISO14001, UL, etc., With constant hard work of our staff and ongoing support from customers both home and abroad, we can provide up to 20 layers, Blind and buried Board, high-precision(Rogers),High TG, Alu-base and flexible boards to our customer with fast turn and high-quality level.We also provide PCB assembly, components sourcing, PCBA function test ,finished products assembly

one-stop service.

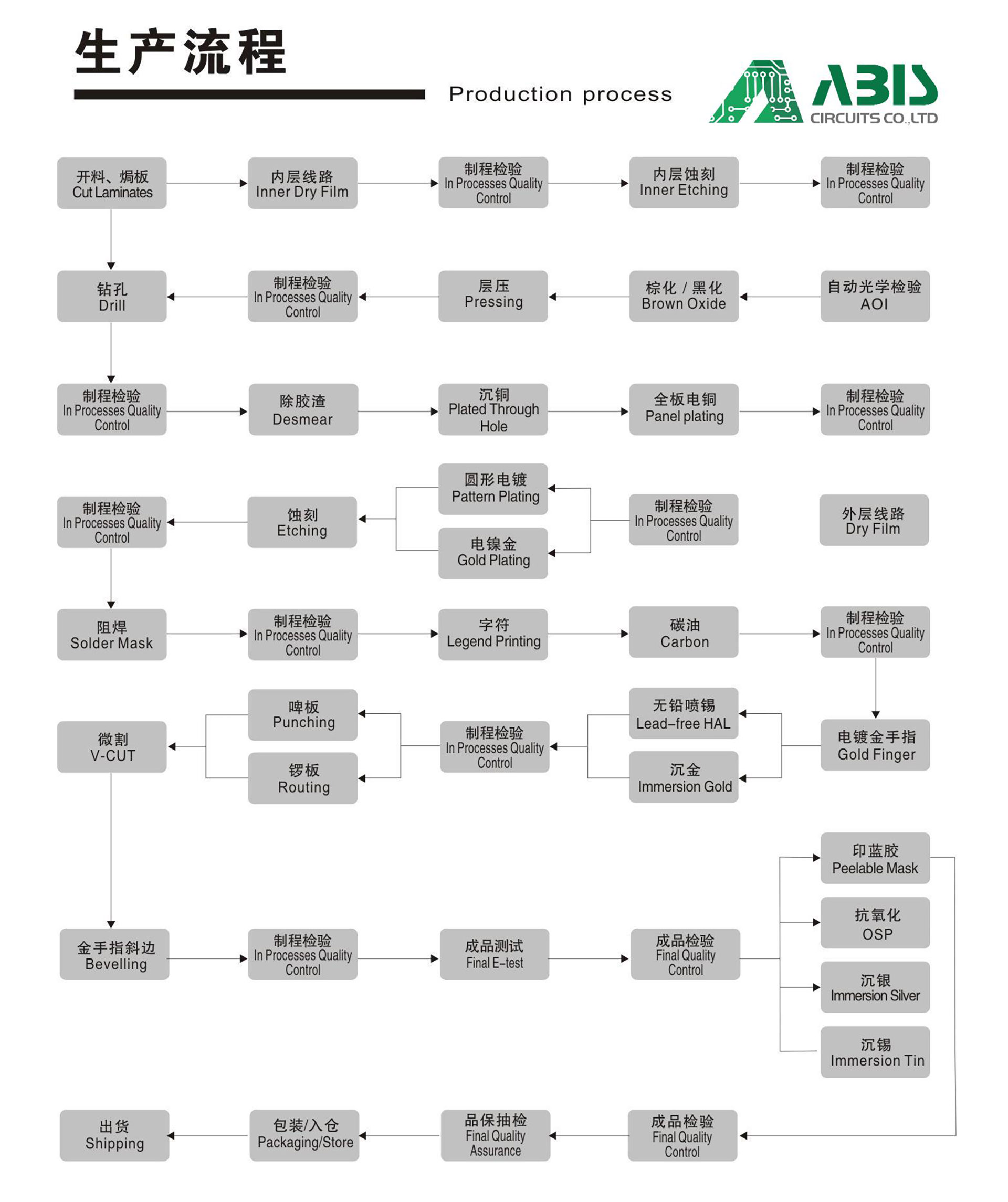

PCB Production Process

Q/T Lead Time

| Category | Quickest Lead Time | Normal Lead Time |

| Double-sided | 24hrs | 120hrs |

| 4 Layers | 48hrs | 172hrs |

| 6 Layers | 72hrs | 192hrs |

| 8 Layers | 96hrs | 212hrs |

| 10 Layers | 120hrs | 268hrs |

| 12 Layers | 120hrs | 280hrs |

| 14 Layers | 144hrs | 292hrs |

| 16-20 Layers | Depends on the specific requirements | |

| Above 20 Layers | Depends on the specific requirements | |

ABIS' move to control FR4 PCBS

- Hole Preparation

Removing debris carefully & adjusting drill machine parameters: before plating through with copper, ABIS pays high attention to all holes on an FR4 PCB treated to remove debris, surface irregularities, and epoxy smear, the clean holes ensure the plating successfully adheres to the hole walls. also, early in the process, drill machine parameters are adjusted accurately.

- Surface Preparation

Deburring carefully: our experienced tech workers will be aware ahead of time that the only way to avoid a bad outcome is to anticipate the need for special handling and to take the appropriate steps to be sure that the process is done carefully and correctly.

- Thermal Expansion Rates

Accustomed to dealing with the various materials, ABIS will be able to analyze the combination to be sure that it is appropriate. then keeping the long-term reliability of the CTE (coefficient of thermal expansion), with the lower CTE, the less likely the plated through holes are to fail from repeated flexing of the copper which forms the internal layer interconnections.

- Scaling

ABIS control the circuitry is scaled-up by known percentages in anticipation of this loss so that the layers will return to their as-designed dimensions after the lamination cycle is complete. also, using the laminate manufacturer’s baseline scaling recommendations in combination with in-house statistical process control data, to dial-in scale factors that will be consistent over time within that particular manufacturing environment.

- Machining

When the time comes to build your PCB, ABIS be sure that you choose has the right equipment and experience to produce it correctly on the first try.

Features-Our Products Advantage

- Over 15 years experience manufacturer in PCB service field

- Big scale of producing makes sure that your purchase cost is lower.

- Advanced production line guarantees stable quality and long life span

- 100% test for all customized PCB products

- One-stop Service ,we can help to purchase the components

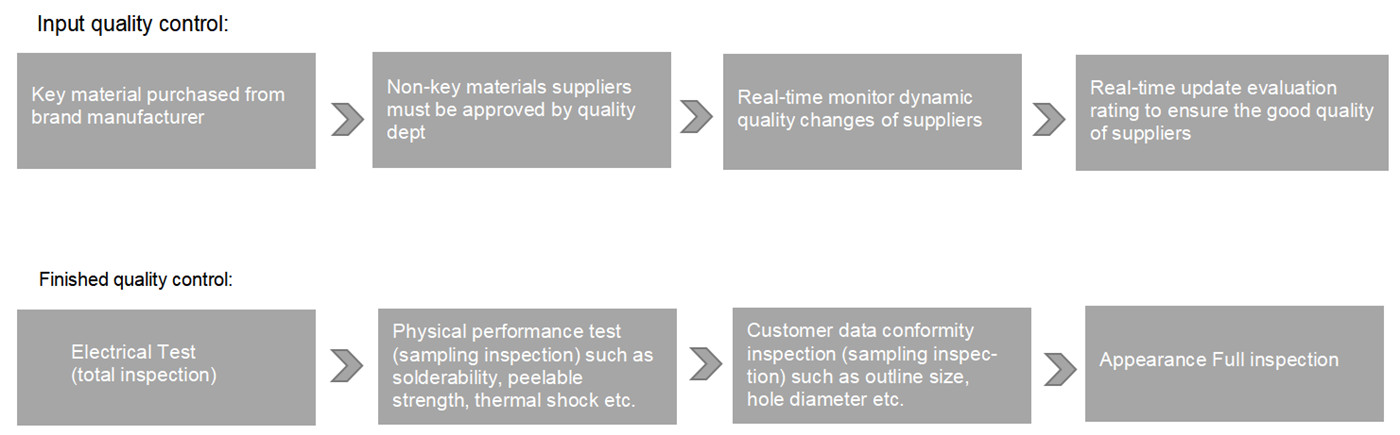

ABIS Quality Mission

- The pass rate of incoming material above 99.9%, the number of mass rejection rates below 0.01%.

- ABIS certified facilities control all key processes to eliminate all potential issues before producing.

- ABIS utilizes advanced software to perform extensive DFM analysis on incoming data, and uses advanced quality control systems throughout the manufacturing process.

- ABIS performs 100% visual and AOI inspection as well as performing electrical testing, high voltage testing, impedance control testing, micro-sectioning, thermal shock testing, solder testing, reliability testing, insulating resistance testing and ionic cleanliness testing.

Certificate

Pre-Sale and After-Sale Service 1 Hour quotation

2 hours of complaint feedback

7*24 hour technical support

7*24 order service

7*24 hour delivery

7*24 production run

Business Terms

-Accepted Delivery Terms

FOB, CIF, EXW, FCA, CPT, DDP, DDU, Express Delivery, DAF

--Accepted Payment Currency

USD, EUR, CNY.

-Accepted Payment Type

T/T, PayPal, Western Union.

Packaging & Delivery

ABIS CIRCUITS Company is not only trying to give customers a good product, but also pay attention to offering a complete and safe package. Also, we prepare some personalized services for all the orders.

-Common packaging:

- PCB: Sealed bag, Anti-static bags, Suitable carton.

- PCBA: Antistatic foam bags, Anti-static bags, Suitable carton.

- Customized Packaging: The carton outside will be printed the name of the customer address, mark, the customer needs to specify the destination and other information.

-Delivery Tips:

- For small package, we advise to choose by Express or DDU service is the quickest way.

- For heavy package, the best solution is by sea transportation.

Why Chose us

- High-end euipment-high speed Pick and Place Machines that can process about 25,000 SMD components per hour

- High efficient supply ability 60K Sqm monthly-Offers low volume and on-demand PCB production, also large-scale production

- Professional engineering team-40 engineers and their own tooling house, strong at OEM. Offers two easy options: Custom and Standard-In-depth knowledge of IPC Class II and III Standards

We provide a comprehensive turn-key EMS service to customers who want us to assemble the PCB into PCBA, including prototypes, NPI project, small and medium volume. We are also able to source all components for your PCB assembly project. Our engineers and sourcing team have rich experience in supply chain and EMS industry, with deep knowledges in SMT assembly allowing to resolve all the production issues. Our service is cost-effective, flexible, and reliable. We have satisfied customers across many industries including medical, industrial, automotive and consumer electronics.

Please keep us informed of any interest!

ABIS cares about every your order even 1 piece!

Most of them from Shengyi Technology Co., Ltd. (SYTECH), who has been the world's second largest CCL manufacturer in terms of sales volume, from 2013 to 2017. We established long-term relations of cooperation since 2006. The FR4 resin material (Model S1000-2, S1141, S1165, S1600) are mainly used for making single and double-sided printed circuit boards as well as multi-layer boards. Here comes details for your reference.

- For FR-4: Sheng Yi, King Board, Nan Ya, Polycard, ITEQ, ISOLA

- For CEM-1 & CEM 3: Sheng Yi, King Board

- For High Frequency : Sheng Yi

- For UV Cure: Tamura, Chang Xing ( * Available colour : Green) Solder for Single Side

- For Liquid Photo: Tao Yang, Resist (Wet Film)

- Chuan Yu ( * Available colors : White, Imaginable Solder Yellow, Purple, Red, Blue, Green, Black)

Each Customer will have a sale to contact you. Our working hours: AM 9:00-PM 19:00(Beijing Time) from Monday to Friday. We will reply to your email as soon as quickly during our working time. And you also could contact our sales by cellphone if urgent.

No, we can't accept picture files, if you no not have Gerber file, can you send us sample to copy it.

Look around you. So many products come from China. Obviously, this has several reasons. It is no longer just about price.

- Preparing quotations is done quickly.

- Production orders are completed quickly. You could plan orders scheduled for months in advance, we can arrange them immediately once PO confirmed.

- Supply chain expanded enormously. That is why we can purchase every component from a specialized partner very quickly.

- Flexible and passionate employees. As a result, we accept every order.

- 24 online service for urgent needs. Working hours of +10 hours per day.

- Lower costs. No hidden cost. Save on personnel, overhead and logistics.

Checked within 12 hours. Once Engineer's question and working file checked, we'll start the production.

Our Quality Assuring Procedures as below:

a),Visual Inspection

b),Flying probe, fixture tool

c), Impedance control

d), Solder-ability detection

e), Digital metallograghic microscope

f),AOI (Automated Optical Inspection)

ABIS has no MOQ requirements for either PCB or PCBA.

ABlS performs 100% visual and AOl inspection as well as performing electrical testing, high voltage testing, impedance control testing, micro-sectioning, thermal shock testing, solder testing, reliability testing, insulating resistance testing, ionic cleanliness testing and PCBA Functional testing.

| Production capacity of hot-sale products | |

| Double Side/Multilayer PCB Workshop | Aluminum PCB Workshop |

| Technical Capability | Technical Capability |

| Raw materials: CEM-1, CEM-3, FR-4(High TG), Rogers, TELFON | Raw materials: Aluminum base, Copper base |

| Layer: 1 layer to 20 Layers | Layer: 1 layer and 2 Layers |

| Min.line width/space: 3mil/3mil(0.075mm/0.075mm) | Min.line width/space: 4mil/4mil(0.1mm/0.1mm) |

| Min.Hole size: 0.1mm(dirilling hole) | Min. Hole size: 12mil(0.3mm) |

| Max. Board size: 1200mm* 600mm | Max.Board size: 1200mm* 560mm(47in* 22in) |

| Finished board thickness: 0.2mm- 6.0mm | Finished board thickness: 0.3~ 5mm |

| Copper foil thickness: 18um~280um(0.5oz~8oz) | Copper foil thickness: 35um~210um(1oz~6oz) |

| NPTH Hole Tolerance: +/-0.075mm,PTH hole Tolerance: +/-0.05mm | Hole position tolerance: +/-0.05mm |

| Outline Tolerance: +/-0.13mm | Routing outline tolerance: +/ 0.15mm; punching outline tolerance:+/ 0.1mm |

| Surface finished: Lead-free HASL, immersion gold(ENIG), immersion silver, OSP, gold plating, gold finger, Carbon INK. | Surface finished: Lead free HASL, immersion gold(ENIG), immersion silver, OSP etc |

| Impedance control tolerance: +/-10% | Remain thickness tolerance: +/-0.1mm |

| Production capability: 50,000 s.q.m/month | MC PCB Production capability: 10,000 s.q.m/month |