Customized High-Quality PCB Assembly for Smart Energy Measurement Devices

Basic Info

| Model No. | PCBA-A56 |

| Assembly method | Post Welding |

| Transport package | Anti-static Packaging |

| Certification | UL, ISO9001&14001, SGS, RoHS, Ts16949 |

| Definitions | IPC Class2 |

| Minimum Space/Line | 0.075mm/3mil |

| Application | Signal transmission |

| Origin | Made in China |

| Production Capacity | 720,000 M2/Year |

PCBA Projects Introduction

ABIS CIRCUITS Company deliver services, not only products. We offer solutions, not only goods.

From the PCB production, the components purchasing to the components assemble. Includes:

PCB Custom

PCB drawing / design according to your schematic diagram

PCB manufacturing

Component sourcing

PCB Assemble

PCBA 100% test

Product Description

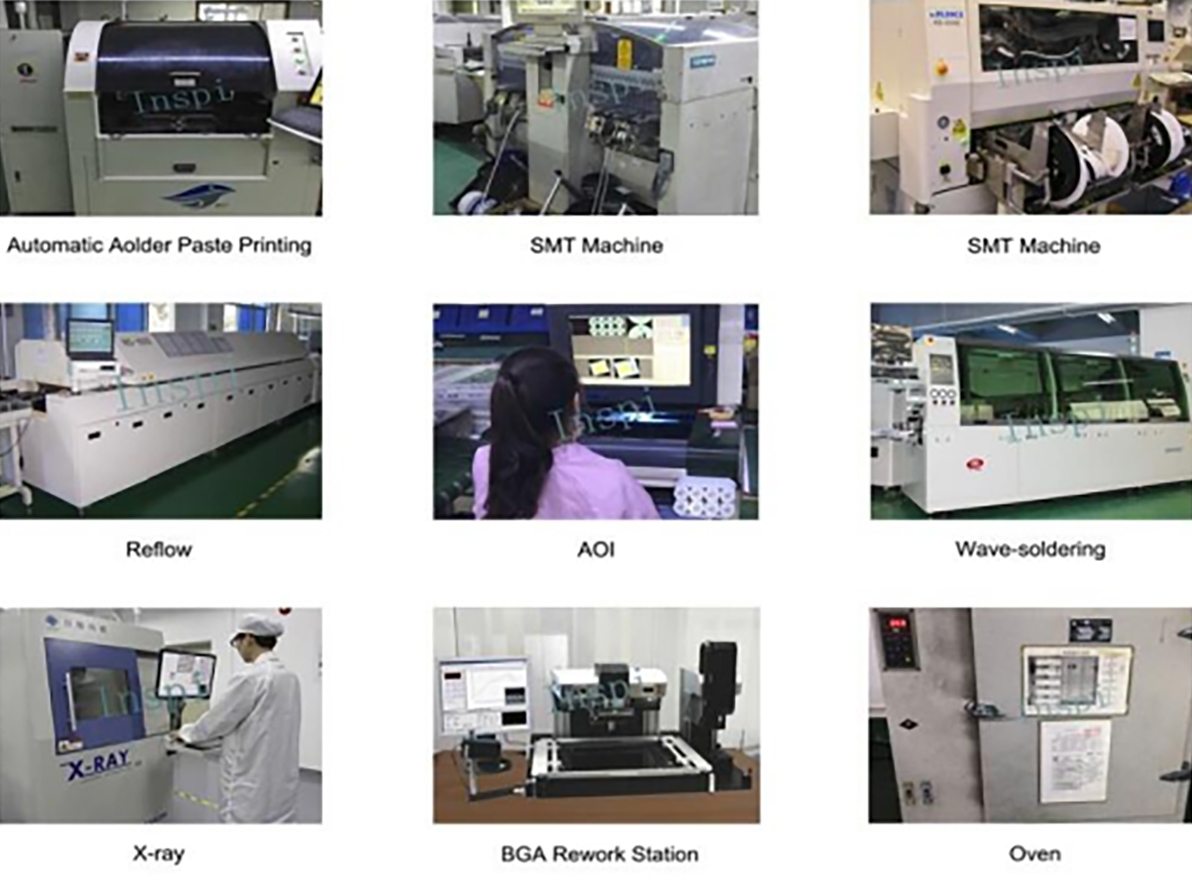

Production Processes

Material Receiving → IQC → Stock → Material to SMT → SMT Line Loading → Solder Paste/Glue Printing → Chip Mount → Reflow → 100% Visual Inspection → Automated Optical Inspection (AOI) → SMT QC Sampling → SMT Stock → Material to PTH → PTH Line Loading → Plated Through Hole → Wave Soldering → Touch Up → 100% Visual Inspection → PTH QC Sampling → In-Circuit Test (ICT) → Final Assembly → Functional Test (FCT) → Packing → OQC Sampling → Shipping

PCBA Capabilities

| 1 | SMT assembly including BGA assembly |

| 2 | Accepted SMD chips: 0204, BGA, QFP, QFN, TSOP |

| 3 | Component height: 0.2-25mm |

| 4 | Min packing: 0201 |

| 5 | Min distance among BGA : 0.25-2.0mm |

| 6 | Min BGA size: 0.1-0.63mm |

| 7 | Min QFP space: 0.35mm |

| 8 | Min assembly size: (X*Y): 50*30mm |

| 9 | Max assembly size: (X*Y): 350*550mm |

| 10 | Pick-placement precision: ±0.01mm |

| 11 | Placement capability: 0805, 0603, 0402 |

| 12 | High pin count press fit available |

| 13 | SMT capacity per day: 80,000 points |

Capability - SMT

|

Lines |

9(5 Yamaha,4KME) |

|

Capacity |

52 million placements per month |

|

Max Board Size |

457*356mm.(18”X14”) |

|

Min Component size |

0201-54 sq.mm.(0.084 sq.inch),long connector,CSP,BGA,QFP |

|

Speed |

0.15 sec/chip,0.7 sec/QFP |

Capability - PTH

|

Lines |

2 |

|

Max board width |

400 mm |

|

Type |

Dual wave |

|

Pbs status |

Lead-free line support |

|

Max temp |

399 degree C |

|

Spray flux |

add-on |

|

Pre-heat |

3 |

Q/T Lead Time

| Category | Quickest Lead Time | Normal Lead Time |

| Double-sided | 24hrs | 120hrs |

| 4 Layers | 48hrs | 172hrs |

| 6 Layers | 72hrs | 192hrs |

| 8 Layers | 96hrs | 212hrs |

| 10 Layers | 120hrs | 268hrs |

| 12 Layers | 120hrs | 280hrs |

| 14 Layers | 144hrs | 292hrs |

| 16-20 Layers | Depends on the specific requirements | |

| Above 20 Layers | Depends on the specific requirements | |

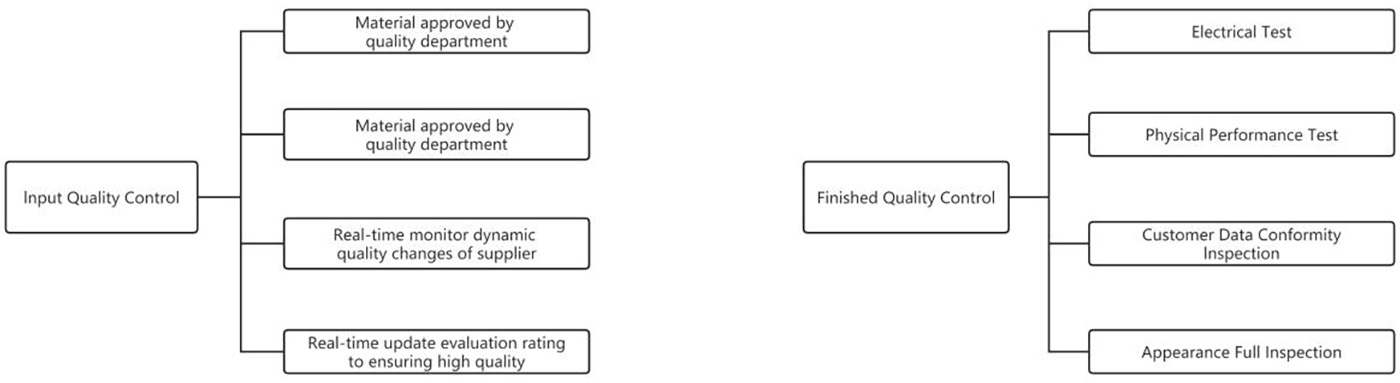

Quality Control

| AOI Testing | Checks for solder pasteChecks for components down to 0201

Checks for missing components, offset, incorrect parts, polarity |

| X-Ray Inspection | X-Ray provides high-resolution inspection of:BGAs/Micro BGAs/Chip scale packages /Bare boards |

| In-Circuit Testing | In-Circuit Testing is commonly used in conjunction with AOI minimizing functional defects caused by component problems. |

| Power-up Test | Advanced Function TestFlash Device Programming

Functional testing |

- IOC incoming inspection

- SPI solder paste inspection

- Online AOI inspection

- SMT first article inspection

- External assessment

- X-RAY-welding inspection

- BGA device rework

- QA inspection

- Anti-static warehousing and shipment

FAQ

A:

Bill of materials (BOM) detailing:

a), Manufacturers parts numbers,

b), Components suppliers' parts number (e.g. Digi-key, Mouser, RS )

c), PCBA sample photos if possible.

d), Quantity

A: Free samples depend on your order quantity.

A:

No, we can't accpet picture files, if you no not have gerber file, can you send us sample to copy it.

PCB&PCBA Copy Process:

A:

Our Quality Assuring Procedures as below:

a),Visual Inspection

b),Flying probe, fixture tool

c), Impedance control

d), Solder-ability detection

e), Digital metallograghic microscope

f),AOI (Automated Optical Inspection)

A: Please send the details inquiry to us, such as the Item Number, Quantity for each item, Quality request, Logo, Payment Terms, Transport method, Discharge place, etc. We will make an accurate quotation for you as soon as possible.

A: Each Customer will have a sale to contact with you. Our working hours: AM 9:00-PM 19:00(Beijing Time) from Monday to Friday. We will reply to your email as soon as quickly during our working time. And you also could contact our sales by cellphone if urgent.

| Production capacity of hot-sale products | |

| Double Side/Multilayer PCB Workshop | Aluminum PCB Workshop |

| Technical Capability | Technical Capability |

| Raw materials: CEM-1, CEM-3, FR-4(High TG), Rogers, TELFON | Raw materials: Aluminum base, Copper base |

| Layer: 1 layer to 20 Layers | Layer: 1 layer and 2 Layers |

| Min.line width/space: 3mil/3mil(0.075mm/0.075mm) | Min.line width/space: 4mil/4mil(0.1mm/0.1mm) |

| Min.Hole size: 0.1mm(dirilling hole) | Min. Hole size: 12mil(0.3mm) |

| Max. Board size: 1200mm* 600mm | Max.Board size: 1200mm* 560mm(47in* 22in) |

| Finished board thickness: 0.2mm- 6.0mm | Finished board thickness: 0.3~ 5mm |

| Copper foil thickness: 18um~280um(0.5oz~8oz) | Copper foil thickness: 35um~210um(1oz~6oz) |

| NPTH Hole Tolerance: +/-0.075mm, PTH hole Tolerance: +/-0.05mm | Hole position tolerance: +/-0.05mm |

| Outline Tolerance: +/-0.13mm | Routing outline tolerance: +/ 0.15mm; punching outline tolerance:+/ 0.1mm |

| Surface finished: Lead-free HASL, immersion gold(ENIG), immersion silver, OSP, gold plating, gold finger, Carbon INK. | Surface finished: Lead free HASL, immersion gold(ENIG), immersion silver, OSP etc |

| Impedance control tolerance: +/-10% | Remain thickness tolerance: +/-0.1mm |

| Production capability: 50,000 s.q.m/month | MC PCB Production capability: 10,000 s.q.m/month |

A: yes, We have a professional drawing engineers' team that you can trust.

A: Yes, we ensure that each piece of PCB, and PCBA will be tested before shipment, and we ensure the goods we sent with good quality.

Our Quality Assuring Procedures as below:

a),Visual Inspection

b),Flying probe, fixture tool

c), Impedance control

d), Solder-ability detection

e), Digital metallograghic microscope

f),AOI (Automated Optical Inspection)

·With ABIS, customers significantly and effectively reduce their global procurement costs. Behind each service provided by ABIS, is hidden a cost-saving for customers.

. We have two shops together, one is for prototype, quick turn, and small volume making. The other is for mass production also for the HDI board, with highly skilled professional employees, for high-quality products with competitive prices and on-time delivery.

. We provide very professional sales, technical and logistic support, on a worldwide basis with 24 hours of complaint feedback.